In the world of industrial manufacturing and logistics, the phrase “bigger is better” often translates to “bigger is riskier.”

Handling oversized loads—whether they are massive turbine components, structural steel beams, or long cylindrical shafts—presents a unique set of challenges that standard safety protocols often fail to address.

The stakes are incredibly high; a single miscalculation can result in catastrophic equipment damage, costly project delays, or, most critically, severe injury to personnel.

Navigating the complexities of heavy material handling requires more than just brute force; it demands a strategic blend of planning, specialized equipment, and unwavering attention to detail.

For facility managers and safety officers, the goal is to create an environment where efficiency does not come at the expense of safety.

By adopting a proactive approach to load management, you can significantly reduce the likelihood of accidents while streamlining your operations. Read on to discover six efficient strategies that will help you handle oversized loads with the precision and care they demand.

1. Prioritize Comprehensive Route and Lift Planning

Before a single piece of machinery is engaged, the most critical work happens on paper (or a digital tablet). Attempting to move an oversized load without a detailed plan is a recipe for disaster.

A comprehensive lift plan involves assessing the weight, center of gravity, and dimensions of the load, as well as mapping out the exact path it will travel.

In dynamic industrial environments, the “path of least resistance” is rarely the safest. You must account for overhead obstructions, narrow passageways, and floor load capacities.

Data from the Bureau of Labor Statistics consistently highlights that a significant percentage of workplace accidents occur due to poor environmental awareness.

By conducting a dry run or a virtual simulation of the move, you can identify potential pinch points and hazards before they become real-world problems. Ensure that every member of the team understands the plan, the sequence of movements, and their specific role in the operation.

2. Select the Correct Rigging Equipment

Using the wrong tool for the job is a common error in heavy lifting. Oversized loads often require specialized rigging gear that goes beyond standard slings and shackles.

The shape and weight distribution of the load dictate the equipment needed. For instance, a top-heavy load requires different rigging geometry than a long, flat load to maintain stability.

Inspect all rigging hardware before use. Look for signs of wear, deformation, or corrosion that could compromise structural integrity. It is also vital to use spreader bars or lifting beams when necessary.

These tools help distribute the load’s weight across multiple points, preventing crushing forces from damaging the object being lifted and ensuring the load remains level. Remember, the working load limit (WLL) of your rigging gear must exceed the total weight of the load, including a safety factor to account for dynamic forces during the lift.

3. Implement Specialized Stabilization Tools for Machining

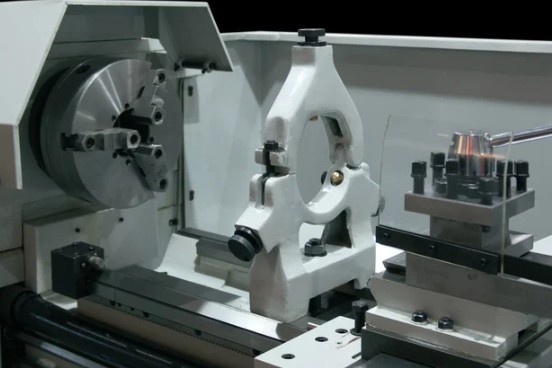

Handling oversized loads isn’t just about moving them from point A to point B; often, these massive components must be held stationary for processing, turning, or machining. When working with long, heavy, or cylindrical parts—such as hydraulic cylinders or drive shafts—gravity becomes an enemy, causing the workpiece to sag or vibrate during rotation.

To combat this, utilizing supportive devices is essential for both safety and quality control. For example, integrating a steady rest into your lathe setup can provide the necessary support to hold a long workpiece steady.

This device clamps around the part, preventing deflection and ensuring that the machining process remains precise. Without such stabilization, the workpiece could wobble, potentially flying out of the machine or shattering tooling, creating a dangerous projectile hazard.

Ensuring your oversized parts are securely supported during processing is just as vital as securing them during transport.

4. Establish Clear Communication Protocols

When the noise of heavy machinery fills the air, verbal communication can easily break down. For a lift to be safe, the crane operator, riggers, and spotters must operate as a single, cohesive unit.

This requires established, standardized communication protocols that everyone understands implicitly.

Standard hand signals are the industry gold standard, but they must be executed clearly and visibly. In scenarios where line-of-sight is compromised, reliable radio communication is non-negotiable.

Designate a single signal person to direct the operator; having multiple people shouting instructions creates confusion and increases the risk of error.

A study by the Occupational Safety and Health Administration (OSHA) emphasizes that communication failures are a leading contributing factor in crane accidents.

Establishing a “stop work” authority—where any team member can halt the operation if they see a safety concern—empowers your workforce and adds an extra layer of security.

5. Conduct Regular Training and Certification

Equipment and protocols are useless without skilled personnel to execute them. The human element is the most variable factor in heavy material handling.

Regular, rigorous training ensures that your team is not only compliant with regulations but also proficient in best practices.

Training should not be a one-time event during onboarding. Continuous education is necessary to keep up with new machinery technologies and updated safety standards. Certification programs for crane operators and forklift drivers ensure that only qualified individuals are handling oversized loads.

Furthermore, conduct “toolbox talks” or safety briefings before specific high-risk lifts to refresh the team’s memory on hazards specific to that day’s task. An educated workforce is a safe workforce, capable of making split-second decisions that can prevent accidents.

6. Prioritize Preventative Equipment Maintenance

The reliability of your lifting and handling equipment is paramount. A hydraulic failure on a forklift or a snapped cable on a crane can have devastating consequences when dealing with tons of material.

Moving from a reactive maintenance schedule to a preventative one ensures that your machinery is always ready for the strain of oversized loads.

Schedule regular inspections for all heavy machinery, looking for hydraulic leaks, tire wear, and structural cracks. Keep detailed logs of all maintenance activities to track the health of your fleet over time.

If a piece of equipment shows signs of potential failure, tag it out immediately. It is far more efficient to delay a lift for a few hours to fix a mechanical issue than to deal with the aftermath of a dropped load. Investing in the upkeep of your tools protects your investment and your people.

Safety in heavy industrial environments is not a destination; it is a continuous process of improvement and vigilance. By implementing these strategies—from rigorous planning and specialized support tools to continuous training—you safeguard your most valuable assets: your employees and your reputation.

Take the time today to review your current handling procedures and identify areas for improvement. A safer, more efficient operation is within your reach.